Xiamen TJ Metal Material Co., Ltd. (referred to as TJ Company) was established in 2009 and is now an important private backbone enterprise in Fujian Province, headquartered in Xiamen City, Fujian Province.

Graphitic Foam – Professional Materials Introduction

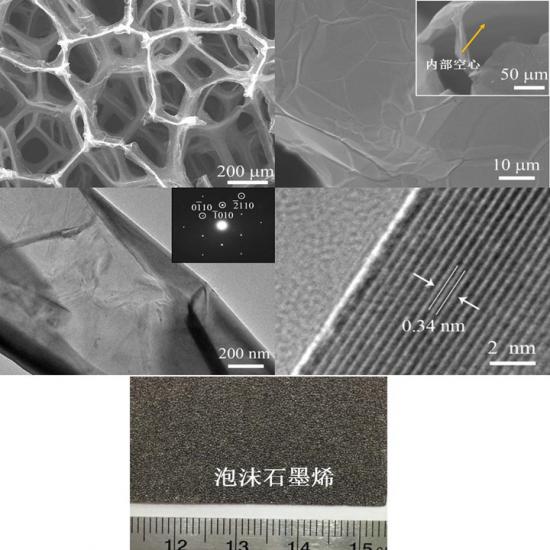

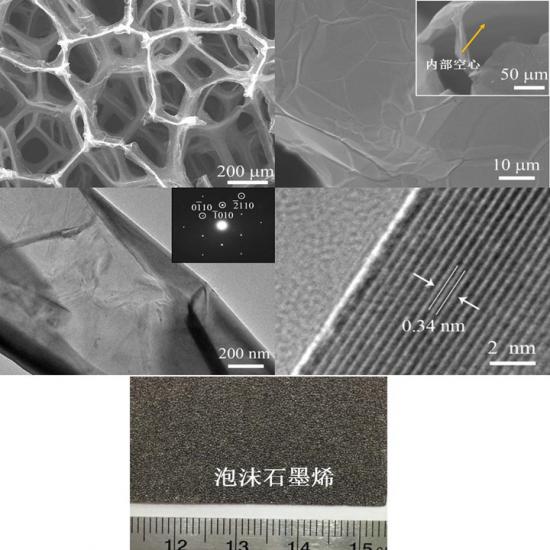

Graphitic foam is an advanced carbonbased material composed of a threedimensional, interconnected network of graphitic ligaments and porous cells. Characterized by extremely low density, high thermal conductivity, excellent mechanical strengthtoweight ratio, and remarkable chemical stability, graphitic foam has become an important functional material for thermal management, structural reinforcement, electrochemical energy storage, and highperformance composites. Its unique combination of graphitic microstructure and foamlike macroporosity offers a multifunctional platform for nextgeneration engineering and scientific applications.

1. Concept of Graphitic Foam

Graphitic foam is produced by graphitizing a carbon precursor—typically polymer foam, metal foam, or carbon foam—at ultrahigh temperatures above 2500–3000°C. During graphitization, carbon atoms rearrange into ordered sp²bonded layers, similar to graphite. The resulting material preserves the lightweight cellular geometry of the precursor while acquiring the crystallinity and conductivity of graphite. This gives graphitic foam a unique hybrid identity: it maintains the rigidity and porosity of a foam but exhibits the electrical, thermal, and mechanical characteristics of graphitic carbon.

2. Structure

The structure of graphitic foam consists of:

• 3D Porous Network

A continuous network of open cells ranging from tens to hundreds of micrometers. The interconnected pores provide high permeability and large surface area.

• Graphitized Ligaments

The walls of the foam are composed of highly ordered graphite layers, often aligned in the plane of the ligament surfaces. This microstructure enables exceptional thermal and electrical conduction.

• Tunable Density and Porosity

Graphitic foam typically has densities between 0.05–0.20 g/cm³, depending on precursor architecture. Porosity can exceed 90%, enabling ultralight performance.

• Multiscale Hierarchy

Macroporous cells, mesoporous channels, and graphitic microcrystals coexist, giving rise to multifunctional properties.

3. Key Characteristics

• High Thermal Conductivity

Graphitic ligaments exhibit thermal conductivities of 100–400 W/m·K, making the foam an excellent heatspreading material for electronics and highpower devices.

• Lightweight Structure

With a density dramatically lower than metals, graphitic foam enables strong, thermally conductive components with minimal mass.

• Superior Electrical Conductivity

The sp² carbon structure ensures low electrical resistivity, allowing its use in electrodes, conductive frameworks, and electromagnetic shielding.

• Outstanding Chemical Stability

Graphitic foam is resistant to oxidation at moderate temperatures, as well as corrosion from acids, alkalis, and organic solvents.

• Mechanical Integrity

Despite its low density, the foam displays high compressive strength and elastic resilience due to the rigid graphitic walls.

4. Manufacturing Processes

Several industrial and laboratory techniques are used to produce graphitic foam:

• Polymer Foam Pyrolysis

Polyurethane or phenolic foams are carbonized at 800–1200°C and graphitized at >2500°C, preserving the original cellular geometry.

• Metal Foam Templating

Nickel or aluminum foams are impregnated with carbon precursors, by carbon deposition and removal of the metal template.

• Chemical Vapor Deposition (CVD)

Hydrocarbon gases are decomposed on metal foam catalysts, forming uniform graphitic coatings with controlled thickness.

• 3D Printing + Graphitization

Additive manufacturing enables customized foam architectures tailored for thermal or mechanical optimization.

Each process influences pore architecture, ligament alignment, graphitization level, and final performance.

5. Applications

Graphitic foam is used across many advanced engineering fields:

• Thermal Management Systems

Heat sinks, heat spreaders, and substrates for power electronics, LEDs, and highfrequency devices.

• Energy Storage

Current collectors, conductive scaffolds, and lightweight porous electrodes for lithiumion, sodiumion, and solidstate batteries.

• Structural Composites

Reinforcement material in polymers and metals where both stiffness and thermal conductivity are required.

• Aerospace and Automotive Engineering

Lightweight thermalcontrol components capable of withstanding extreme temperature gradients.

• Catalysis and Chemical Processing

Support structures with high surface area and chemical durability for heterogeneous catalysts.

• EMI Shielding and Sensors

Conductive and mechanically stable networks for electromagnetic shielding materials, strain sensors, and multifunctional electronics.

Graphene Metal Foam

6. Advantages

• Exceptional Thermal Performance

Graphitic foam spreads heat more effectively than many metals while weighing only a fraction as much.

• High StrengthtoWeight Ratio

The cellular structure provides rigidity without adding mass, essential for aerospace and portable electronics.

• Design Flexibility

Pore sizes, densities, and microstructures can be tuned for specific applications.

• Energy Efficiency

Highly conductive foam reduces energy loss in thermal and electrical systems.

• Environmental Stability

Nontoxic, chemically inert, and resistant to degradation, making it suitable for longterm use.

• Compatibility with Composites

Easily integrated into resins, metals, and ceramics to create multifunctional hybrid materials.

Conclusion

Graphitic foam represents a unique class of advanced carbon materials that integrates the superior thermal, electrical, and mechanical properties of graphite with the ultralight, porous architecture of foam structures. Its high conductivity, tunable porosity, mechanical resilience, and chemical stability make it an unparalleled candidate for nextgeneration thermal systems, lightweight structural components, electrochemical devices, and multifunctional composites. As manufacturing technologies continue to advance, graphitic foam will play an increasingly important role in highperformance engineering and materials science.

If you want, I can also write articles for graphene foam, graphite foam battery, graphene oxide foam, or any other material.

low is a 700–800word professional materialsintroduction article using the keyword “graphitic foam.”

Graphitic Foam – Professional Materials Introduction

Graphitic foam is an advanced carbonbased material composed of a threedimensional, interconnected network of graphitic ligaments and porous cells. Characterized by extremely low density, high thermal conductivity, excellent mechanical strengthtoweight ratio, and remarkable chemical stability, graphitic foam has become an important functional material for thermal management, structural reinforcement, electrochemical energy storage, and highperformance composites. Its unique combination of graphitic microstructure and foamlike macroporosity offers a multifunctional platform for nextgeneration engineering and scientific applications.

1. Concept of Graphitic Foam

Graphitic foam is produced by graphitizing a carbon precursor—typically polymer foam, metal foam, or carbon foam—at ultrahigh temperatures above 2500–3000°C. During graphitization, carbon atoms rearrange into ordered sp²bonded layers, similar to graphite. The resulting material preserves the lightweight cellular geometry of the precursor while acquiring the crystallinity and conductivity of graphite. This gives graphitic foam a unique hybrid identity: it maintains the rigidity and porosity of a foam but exhibits the electrical, thermal, and mechanical characteristics of graphitic carbon.

2. Structure

The structure of graphitic foam consists of:

• 3D Porous Network

A continuous network of open cells ranging from tens to hundreds of micrometers. The interconnected pores provide high permeability and large surface area.

• Graphitized Ligaments

The walls of the foam are composed of highly ordered graphite layers, often aligned in the plane of the ligament surfaces. This microstructure enables exceptional thermal and electrical conduction.

• Tunable Density and Porosity

Graphitic foam typically has densities between 0.05–0.20 g/cm³, depending on precursor architecture. Porosity can exceed 90%, enabling ultralight performance.

• Multiscale Hierarchy

Macroporous cells, mesoporous channels, and graphitic microcrystals coexist, giving rise to multifunctional properties.

3. Key Characteristics

• High Thermal Conductivity

Graphitic ligaments exhibit thermal conductivities of 100–400 W/m·K, making the foam an excellent heatspreading material for electronics and highpower devices.

• Lightweight Structure

With a density dramatically lower than metals, graphitic foam enables strong, thermally conductive components with minimal mass.

• Superior Electrical Conductivity

The sp² carbon structure ensures low electrical resistivity, allowing its use in electrodes, conductive frameworks, and electromagnetic shielding.

• Outstanding Chemical Stability

Graphitic foam is resistant to oxidation at moderate temperatures, as well as corrosion from acids, alkalis, and organic solvents.

• Mechanical Integrity

Despite its low density, the foam displays high compressive strength and elastic resilience due to the rigid graphitic walls.

4. Manufacturing Processes

Several industrial and laboratory techniques are used to produce graphitic foam:

• Polymer Foam Pyrolysis

Polyurethane or phenolic foams are carbonized at 800–1200°C and graphitized at >2500°C, preserving the original cellular geometry.

• Metal Foam Templating

Nickel or aluminum foams are impregnated with carbon precursors, by carbon deposition and removal of the metal template.

• Chemical Vapor Deposition (CVD)

Hydrocarbon gases are decomposed on metal foam catalysts, forming uniform graphitic coatings with controlled thickness.

• 3D Printing + Graphitization

Additive manufacturing enables customized foam architectures tailored for thermal or mechanical optimization.

Each process influences pore architecture, ligament alignment, graphitization level, and final performance.

5. Applications

Graphitic foam is used across many advanced engineering fields:

• Thermal Management Systems

Heat sinks, heat spreaders, and substrates for power electronics, LEDs, and highfrequency devices.

• Energy Storage

Current collectors, conductive scaffolds, and lightweight porous electrodes for lithiumion, sodiumion, and solidstate batteries.

• Structural Composites

Reinforcement material in polymers and metals where both stiffness and thermal conductivity are required.

• Aerospace and Automotive Engineering

Lightweight thermalcontrol components capable of withstanding extreme temperature gradients.

• Catalysis and Chemical Processing

Support structures with high surface area and chemical durability for heterogeneous catalysts.

• EMI Shielding and Sensors

Conductive and mechanically stable networks for electromagnetic shielding materials, strain sensors, and multifunctional electronics.

6. Advantages

• Exceptional Thermal Performance

Graphitic foam spreads heat more effectively than many metals while weighing only a fraction as much.

• High StrengthtoWeight Ratio

The cellular structure provides rigidity without adding mass, essential for aerospace and portable electronics.

• Design Flexibility

Pore sizes, densities, and microstructures can be tuned for specific applications.

• Energy Efficiency

Highly conductive foam reduces energy loss in thermal and electrical systems.

• Environmental Stability

Nontoxic, chemically inert, and resistant to degradation, making it suitable for longterm use.

• Compatibility with Composites

Easily integrated into resins, metals, and ceramics to create multifunctional hybrid materials.

Conclusion

Graphitic foam represents a unique class of advanced carbon materials that integrates the superior thermal, electrical, and mechanical properties of graphite with the ultralight, porous architecture of foam structures. Its high conductivity, tunable porosity, mechanical resilience, and chemical stability make it an unparalleled candidate for nextgeneration thermal systems, lightweight structural components, electrochemical devices, and multifunctional composites. As manufacturing technologies continue to advance, graphitic foam will play an increasingly important role in highperformance engineering and materials science.