Xiamen TJ Metal Material Co., Ltd. (referred to as TJ Company) was established in 2009 and is now an important private backbone enterprise in Fujian Province, headquartered in Xiamen City, Fujian Province.

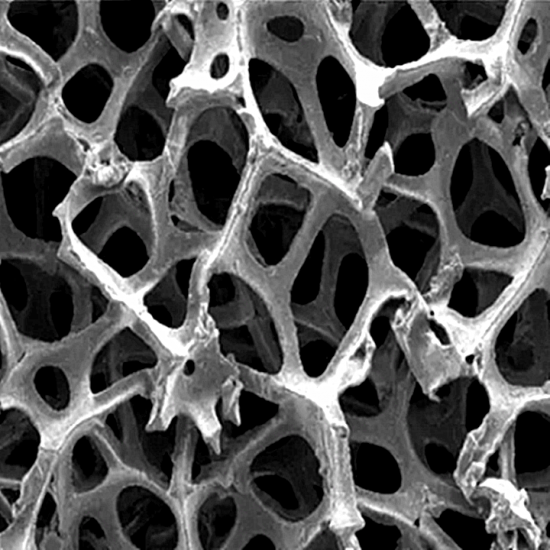

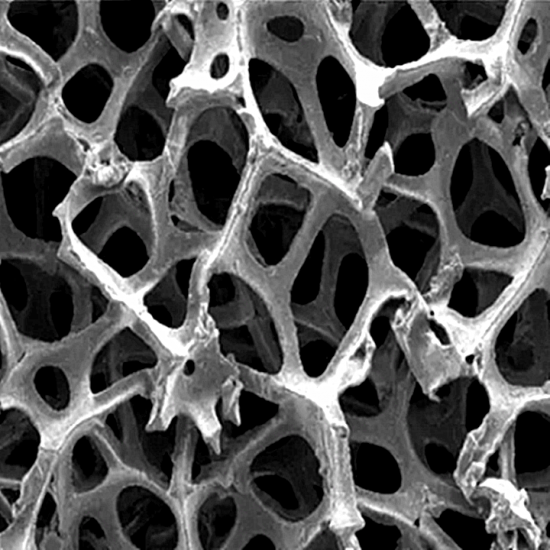

Graphene Foam – Professional Material Introduction

Graphene foam is an ultralight, threedimensional (3D) carbon nanomaterial composed of interconnected graphene sheets arranged in a porous, opencell architecture. It combines the extraordinary electrical, mechanical, and thermal properties of graphene with the structural benefits of a foamlike network, resulting in a multifunctional material suitable for cuttingedge applications in energy storage, thermal management, sensors, composites, catalysis, and biomedical engineering. Because of its high surface area, excellent conductivity, and robust 3D framework, graphene foam represents one of the most promising advanced materials for nextgeneration technologies.

1. Concept of Graphene Foam

Graphene foam is created by assembling twodimensional graphene sheets into a 3D macroporous network. Unlike traditional graphene powders, films, or flakes, graphene foam maintains continuous electrical pathways and strong structural integrity throughout the entire material. Its density is extremely low—often less than 10 mg/cm³—while retaining impressive mechanical resilience. This makes graphene foam ideal for applications where lightweight, conductive, and highsurfacearea materials are essential.

2. Structural Characteristics

The structure of graphene foam consists of:

• ThreeDimensional Network

Graphene sheets and multilayer graphene form an interconnected scaffold, providing large pore sizes (20–500 µm) and a highly open structure.

• High Surface Area

The material can reach surface areas of several hundred m²/g, enabling high reaction activity or loading capacity.

• Continuous Conductive Pathways

The 3D carbon skeleton supports excellent electron transport, significantly outperforming granular or powdered graphene materials.

• Tunable Pore Architecture

The porosity, density, and pore arrangement can be adjusted during fabrication, allowing customization for specific applications such as electrodes, filters, or catalysts.

• Mechanical Flexibility

Despite its ultralight density, graphene foam exhibits robust compressibility, elasticity, and structural stability.

3. Key Material Properties

• Outstanding Electrical Conductivity

The highquality graphene network ensures efficient electron transport, making the foam ideal for electrochemical and electronic applications.

• Exceptional Mechanical Strength

Graphene foam can withstand large compressive strains while maintaining structural integrity due to its strong carbon–carbon bonding.

• Excellent Thermal Conductivity

The continuous carbon network allows rapid heat transfer, beneficial for thermal interface materials or heat spreaders.

• Chemical Stability

Graphene foam resists oxidation, chemical corrosion, and degradation, enabling longterm use in harsh environments.

• Large Specific Surface Area

This feature supports high catalytic activity, significant energystorage capability, and effective adsorption performance.

• Lightweight and Porous

The density is extremely low, enabling energyefficient, materialsaving, and lightweight engineering designs.

4. Fabrication Processes

Graphene foam is commonly produced through the following techniques:

• Chemical Vapor Deposition (CVD)

A metal foam template (often nickel) is coated with graphene via CVD, then the template is etched away to leave a pure graphene network. This method produces highquality, monolithic graphene foam.

• TemplateAssisted Assembly

Polymer foams or ceramic scaffolds serve as templates coated with graphene oxide or reduced graphene oxide, by thermal reduction and carbonization.

• FreezeDrying of Graphene Hydrogels

Graphene oxide suspensions are gelled, frozen, and freezedried to produce ultralight aerogellike graphene foams.

• 3D Printing and Additive Manufacturing

Emerging techniques allow controlled printing of grapheneink structures to create customizable foam geometries.

Each fabrication method offers different advantages in terms of cost, mechanical properties, and purity.

CVD Graphene Foam

5. Applications of Graphene Foam

• Energy Storage Devices

Used as highperformance anodes and cathodes in lithiumion, sodiumion, and lithium–sulfur batteries due to its conductivity and large surface area. Also ideal as supercapacitor electrodes.

• Thermal Management Materials

Functions as heat spreaders and thermal interface materials in electronics, thanks to excellent thermal conductivity.

• Sensors

The foam's large surface area makes it highly sensitive to pressure, chemicals, gases, and biological molecules.

• Catalysis and Electrocatalysis

Serves as an efficient support for catalysts, offering high reaction activity and strong durability.

• Lightweight Structural Composites

Incorporated into polymers or metals to form strong, conductive, and lightweight composite materials.

• Environmental Filtration

Used for water purification, oil adsorption, and removal of pollutants due to its highly porous structure.

• Biomedical Engineering

Explored for scaffold materials in tissue engineering and for drugdelivery platforms.

6. Advantages of Graphene Foam

• Superior Conductivity

Ensures excellent performance in electronics and electrochemical devices.

• High StrengthtoWeight Ratio

Allows the creation of lightweight yet robust materials and components.

• Versatile Structural Design

Pore size and density can be customized for different functional needs.

• Outstanding Stability

Maintains performance across a wide range of temperatures and chemical environments.

• Enhanced Surface Functionality

Supports high loading of active materials, enabling improvement of energy storage and catalytic processes.

• MultiField Adaptability

Its unique combination of conductivity, porosity, and mechanical resilience enables applications across energy, environmental, medical, and industrial sectors.

Conclusion

Graphene foam is a groundbreaking 3D nanomaterial that combines graphene’s exceptional physical and chemical properties with an ultralight, porous structure. With remarkable conductivity, mechanical resilience, thermal stability, and tunable porosity, it has become indispensable in energy technologies, thermal systems, sensors, composites, environmental engineering, and highend research. As fabrication methods continue to advance, graphene foam is expected to play an increasingly vital role in nextgeneration materials and device innovation.