Xiamen TJ Metal Material Co., Ltd. (referred to as TJ Company) was established in 2009 and is now an important private backbone enterprise in Fujian Province, headquartered in Xiamen City, Fujian Province.

Graphene Foam for Sale – Professional Material Introduction

Graphene foam for sale refers to commercially available, threedimensional (3D) graphene architectures engineered for highperformance thermal, electrical, mechanical, and electrochemical applications. As an advanced nanomaterial, graphene foam combines the extraordinary intrinsic properties of graphene with a porous, interconnected, ultralight framework, making it ideal for nextgeneration batteries, sensors, thermal interface materials, composites, and electromagnetic shielding. The growing availability of graphene foam in research and industry reflects rapid advances in scalable synthesis, structural engineering, and applicationdriven customization.

1. Concept of Graphene Foam

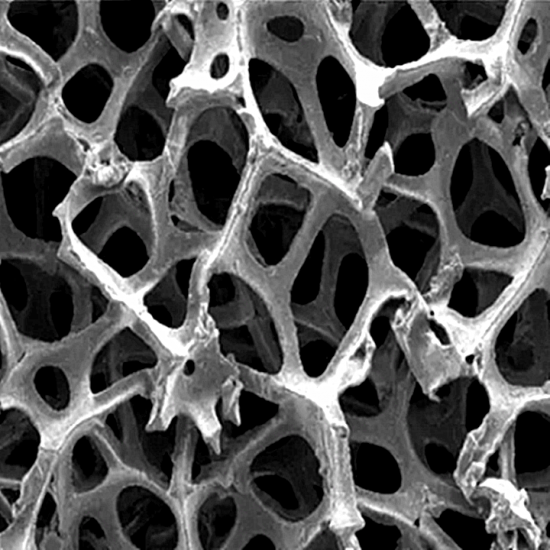

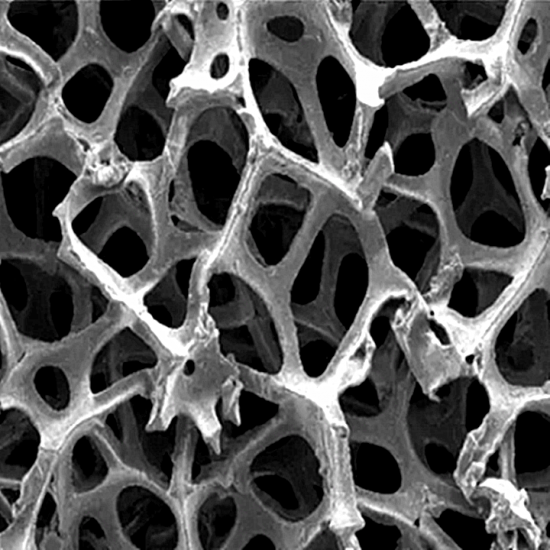

Graphene foam is a3D porous network composed of interconnected graphene sheets with extremely high surface area, low density, and excellent conductivity. Unlike conventional bulk graphene powder, graphene foam retains continuous electrical pathways and mechanical integrity due to its monolithic structure. The foam typically possesses porosity levels above95%, densities as low as5–20 mg/cm³, and large specific surface areas reaching several hundred m²/g.

Commercial “graphene foam for sale” is typically offered in fixed dimensions, customizable shapes, and tunable pore sizes to meet the needs of academic laboratories, electronics manufacturers, and energystorage developers.

2. Structural Characteristics

Graphene foam exhibits a unique multiscale architecture composed of:

• Interconnected Graphene Network

The foam consists of a seamless, conductive lattice of fewlayer graphene sheets grown or deposited onto a 3D template.

• Tunable Pore Structure

Pores range fromtens to hundreds of micrometers, depending on synthesis method. Controlled porosity ensures optimal mass and heat transfer.

• Lightweight skeletal framework

Its ultralow density enables flexible handling, integration into composites, or direct incorporation into devices.

• High Mechanical Resilience

Despite being lightweight, the foam displays excellent compressive strength and elastic recovery due to its cellular architecture.

• HighPurity Carbon Composition

Commercial products often exceed99% carbon purity, minimizing defects and ensuring reliable performance.

3. Material Properties

Graphene foam demonstrates several exceptional characteristics:

• Superior Electrical Conductivity

Continuous graphene pathways enable fast electron transport, ideal for electrodes and conductive frameworks.

• High Thermal Conductivity

The foam structure rapidly dissipates heat, making it suitable for heat spreaders and thermal management systems.

• Large Specific Surface Area

The high surface area promotes rapid electrochemical reactions or effective adsorption of molecules.

• Chemical and Thermal Stability

Graphene foam resists oxidation at moderate temperatures, and remains stable in various chemical environments.

• Mechanical Robustness

The foam withstands repeated compression cycles and maintains structural integrity, critical for flexible and wearable electronics.

4. Manufacturing Processes

Commercial graphene foam is produced through several scalable fabrication methods:

• Chemical Vapor Deposition (CVD)

Graphene is grown directly on nickel or copper foam templates, which are later etched away to yield freestanding graphene foam. This process offers the highest conductivity and structural quality.

• PolymerDerived Carbonization

Polymeric foams coated with graphene oxide are carbonized to form conductive 3D graphene networks.

• FreezeDrying and SelfAssembly

Graphene oxide dispersions form aerogeltype foams via freezedrying and thermal reduction, allowing precise control over pore size.

• 3D Printing and Additive Manufacturing

Emerging techniques allow the direct printing of graphenebased inks into designed foam architectures.

Commercial suppliers often classify “graphene foam for sale” based on thickness, pore size, conductivity, and purity.

3D Graphene

5. Applications

Graphene foam’s multifunctional performance makes it valuable across a wide range of sectors:

• Energy Storage

Used as electrodes or conductive frameworks in:

Lithiumion and sodiumion batteries

Supercapacitors

Metal–air batteries

Electrocatalytic systems

The foam enhances ion transport and improves cell cyclability.

• Thermal Management

Graphene foam serves as a lightweight heat spreader or thermal interface material in electronics, LEDs, and highpower devices.

• Composite Reinforcement

When integrated into polymer or metal matrices, graphene foam enhances strength, flexibility, and conductivity.

• Sensors and Wearable Devices

Its large surface area and high conductivity enable sensitive detection of pressure, strain, gases, and humidity.

• EMI Shielding

The interconnected carbon network effectively absorbs and reflects electromagnetic radiation.

• Catalysis and Environmental Applications

Graphene foam supports catalysts or adsorbs pollutants due to its porous structure.

6. Advantages

• High PerformancetoWeight Ratio

The extremely lightweight structure delivers exceptional conductivity and mechanical strength.

• Excellent Integration Capability

Foam can be cut, shaped, or laminated into various device architectures.

• Enhanced Functionality Compared to 2D Graphene

The 3D network prevents restacking, preserving conductivity and active sites.

• Scalable and Customizable

Commercial suppliers offer customizable dimensions, thicknesses, and densities to meet specific project needs.

• CostEffective for Research

Availability of standardized foam sheets provides affordable access for laboratories developing advanced materials.

Conclusion

Graphene foam for sale represents one of the most versatile and highperformance carbonbased materials currently available. Its unique 3D porous graphene architecture provides unmatched electrical, thermal, and mechanical performance, supporting nextgeneration innovation in energy storage, thermal management, electronics, composites, and advanced sensing. As manufacturing techniques mature, graphene foam continues to become more affordable and widely available, offering researchers and industry professionals an exceptional platform for cuttingedge applications.