Xiamen TJ Metal Material Co., Ltd. (referred to as TJ Company) was established in 2009 and is now an important private backbone enterprise in Fujian Province, headquartered in Xiamen City, Fujian Province.

Carbon Foam Battery – Professional Material Introduction

A carbon foam battery is an advanced energystorage technology that utilizes carbon foam as a structural and functional component within the battery’s electrode architecture. Carbon foam is an ultralightweight, threedimensional porous carbon material characterized by high electrical conductivity, thermal stability, and an interconnected opencell network. When incorporated into battery systems, carbon foam significantly enhances electrochemical performance by improving ion transport, current distribution, and thermal management. As the global demand for highpower, longcycle, and safe energystorage devices continues to rise, the carbon foam battery has emerged as a promising nextgeneration solution for energy, transportation, and gridstorage industries.

1. Concept of the Carbon Foam Battery

A carbon foam battery refers to a battery system—typically lead–acid, lithiumion, sodiumion, or hybrid chemistries—in which carbon foam replaces traditional metal grids or solid electrodes. The opencell framework of carbon foam provides a large surface area for activematerial loading and efficient electrochemical reactions. This threedimensional conductive matrix not only reduces internal resistance but also enhances electrolyte utilization and energy density. Compared with conventional electrodes that rely on flat or twodimensional structures, carbon foam enables true volumetric electrode designs that support higher reaction kinetics and improved charge–discharge performance.

2. Structure and Composition

Carbon foam used in batteries generally features:

• ThreeDimensional Porous Network

An interconnected carbon skeleton with pore sizes typically ranging from micrometers to millimeters, forming a lightweight and mechanically robust foam.

• Graphitic or SemiGraphitic Carbon Walls

These offer high conductivity, stability, and compatibility with diverse electrolytes.

• Tunable Porosity and Density

Porosity can exceed 90%, creating an enormous surface area for electrochemical reactions. Density ranges from 0.05 to 0.6 g/cm³ depending on application requirements.

• Surface Functionalization

Processes such as oxidation, doping, or coating can enhance wettability, catalytic activity, or activematerial adhesion.

In a carbon foam battery, the foam structure serves as:

a current collector,

a supporting scaffold for active materials,

a thermal dissipation framework,

and sometimes an active electrochemical component.

This multifunctionality significantly simplifies electrode design and improves overall system performance.

3. Material Characteristics

Carbon foam exhibits several key properties that make it ideal for battery applications:

• High Electrical Conductivity

Graphitic carbon walls provide fast electron transport and uniform current distribution.

• Exceptional Thermal Conductivity

Effective heat dissipation prevents thermal hotspots and enhances battery safety.

• High Surface Area and Open Porosity

Supports large activematerial loading and efficient electrolyte penetration.

• Chemical and Electrochemical Stability

Resistant to oxidation, corrosion, and electrolyte degradation, ensuring long operational life.

• Low Density and High Mechanical Strength

Provides structural stability without adding significant weight to the battery.

These combined properties enable carbon foam batteries to deliver superior power performance, cycle stability, and thermal robustness.

4. Manufacturing and Processing

The fabrication of carbon foam for battery systems generally involves:

• Polymer or Pitch Foaming

Precursors such as phenolic resin, polyurethane, or coaltar pitch are expanded into foam structures through thermal or chemical blowing.

• Carbonization

The foam is heated at 600–1000°C under inert atmosphere to convert it into carbon.

• Graphitization (Optional)

To enhance conductivity, further heat treatment at 2000–3000°C increases graphitic ordering.

• Surface Modification

Oxidation, plasma treatment, doping (N, B, P), or coating improves electrochemical compatibility.

• ActiveMaterial Deposition

Techniques include slurry coating, infiltration, electrodeposition, or vapor deposition to integrate batteryspecific active materials (e.g., PbO₂, LiCoO₂, sulfur, or metal oxides).

This flexible manufacturing sequence allows precise control of pore structure, mechanical strength, and electrochemical functionality.

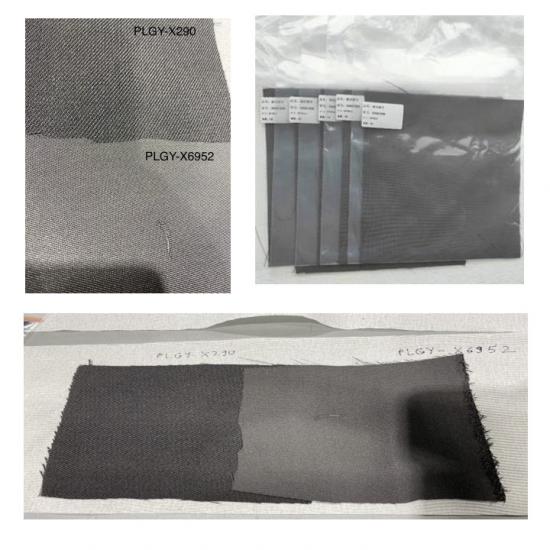

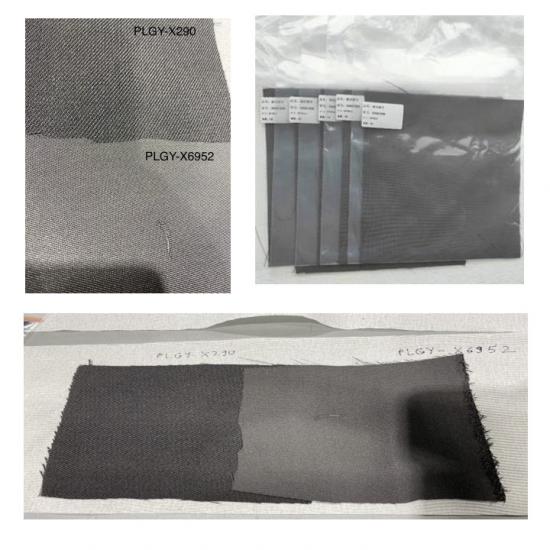

Electrode Cloth

5. Applications

Carbon foam batteries are widely used across multiple sectors:

• Renewable Energy Storage

Wind and solar installations benefit from long cycle life and fast charge–discharge capabilities.

• Electric Vehicles and Hybrid Systems

The material’s high power density and thermal stability enhance safety and performance in demanding automotive environments.

• Grid and Industrial Energy Systems

Carbonfoamenhanced lead–carbon batteries are ideal for largescale energy storage requiring durability and resilience.

• Military and Aerospace

Lightweight foam structures support compact highoutput batteries with exceptional temperature resistance.

• Consumer Electronics

Nextgeneration lithiumion and metalair cells using carbon foam can achieve improved power performance and extended lifespan.

6. Advantages

• Superior Power Capability

The 3D conductive network reduces internal resistance and supports highrate charging and discharging.

• Extended Cycle Life

Prevents sulfation (for leadbased systems) and maintains structural integrity even after thousands of cycles.

• Outstanding Thermal Management

Effective heat dissipation minimizes thermal runaway risk in highpower applications.

• Higher Energy Efficiency

Improved ion distribution and reaction uniformity reduce losses during operation.

• Lightweight and Durable

A lowdensity, mechanically strong structure enhances the battery’s energytoweight ratio.

• Versatility Across Chemistries

Compatible with lithiumion, sodiumion, lead–carbon, zinc–air, and experimental solidstate systems.

Conclusion

The carbon foam battery represents a cuttingedge material solution for highperformance energystorage technologies. Its unique 3D architecture, excellent conductivity, thermal stability, and versatile chemical compatibility provide significant advantages over traditional electrode materials. As energy systems evolve toward higher power density, greater safety, and longer lifespan, carbonfoambased batteries are poised to become a major platform in advanced energy storage for renewable energy, electric mobility, industrial applications, and nextgeneration electronics.