item no.:

TJ-SALF9order(moq):

1Payment:

Credit Card, Paypal, T/T , Western Unionproduct origin:

Chinashipping port:

XiamenLead Time:

In StockHigh-Purity Al Alloy Metal Foam Spherical Open Cell Aluminum Foam For Lab & RD

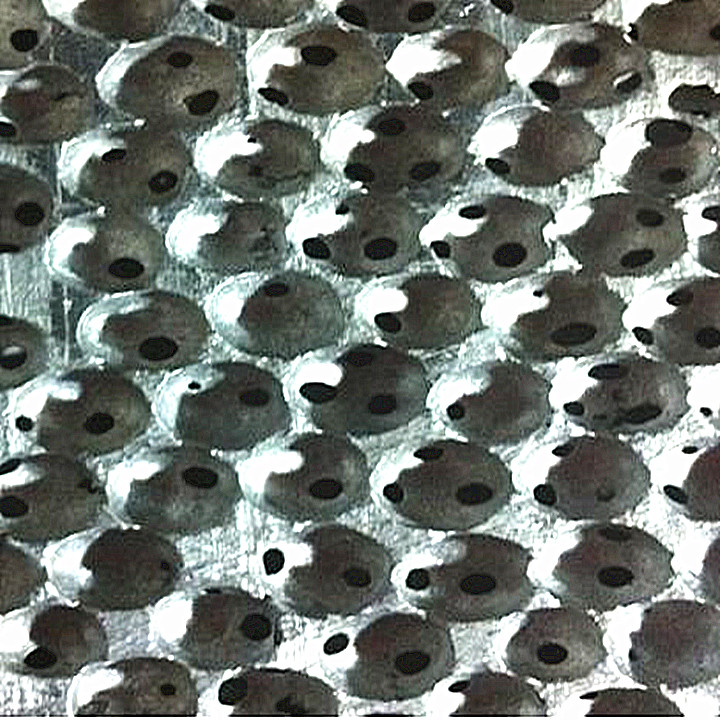

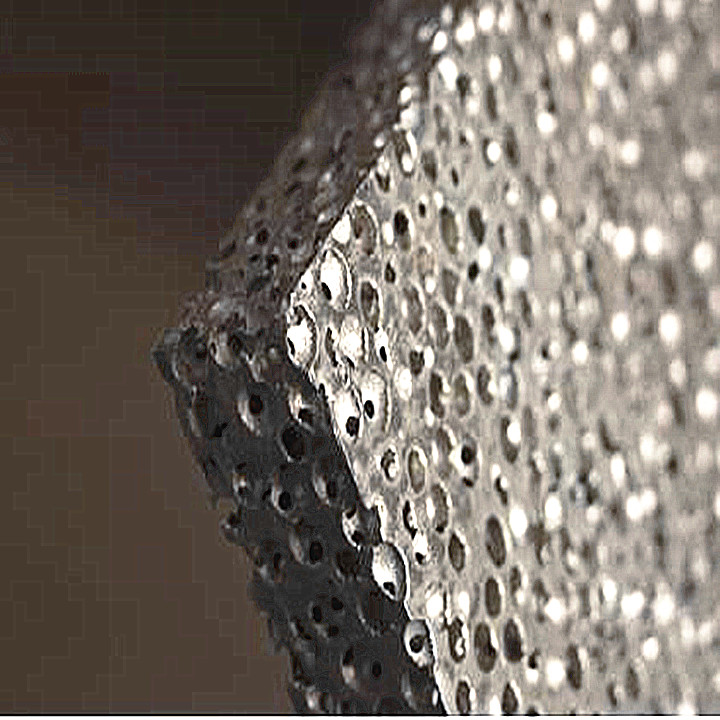

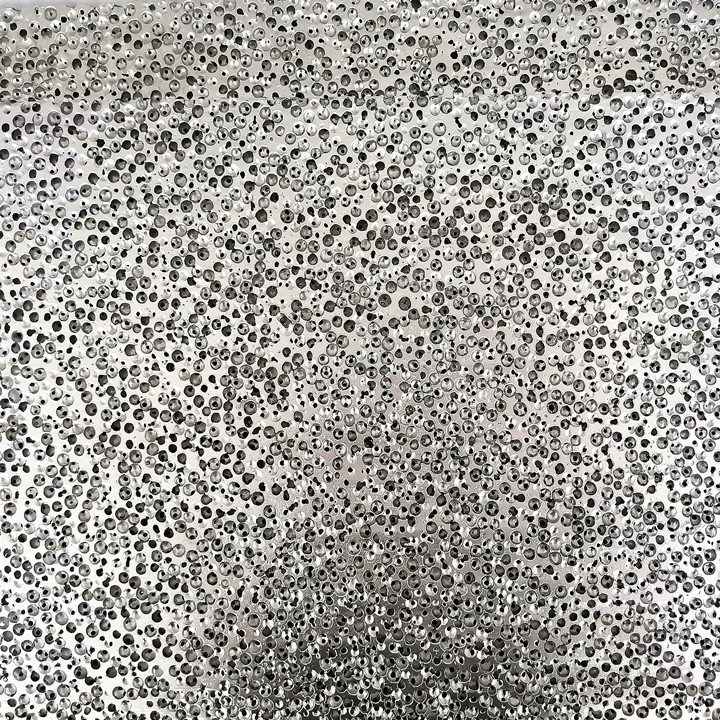

Pore characteristics and bulk density,As for spherical open cell aluminum foam, its bubble chamber is spherical and relatively regular. The bulkhead is provided with small round holes to connect with the sphere, and the holes are divided into six directions to avoid straight through holes, which is conducive to sound absorption, filtering and noise elimination. In practical application, the ideal application effect can be obtained by designing and controlling the ball size (diameter 4-13mm), wall hole size (diameter 0.5-4mm), hole wall thickness and plate thickness. Bulk density: 0.5-0.8g/cm3. The national building materials testing center of the Ministry of construction has identified that the noise reduction coefficient of spherical aluminum foam exceeds international standards. The spherical foamed aluminum products produced by our company is a kind of material that combines the advantages of open holes and closed holes to overcome the shortcomings of open holes and closed holes.

Spherical foam aluminum is an excellent product of foam aluminum acoustic material at home and abroad. It is suitable for noise elimination and noise reduction of various vehicle boxes and mechanical equipment. Due to the uniform distribution of spheres, the same hole shape and regular hole wall, the specific absorption energy is longer. It has excellent impact resistance. Compared with the irregular pores of closed cell aluminum foam, the open hole wall of the sphere is not liable to fracture when subjected to impact. It is used as shock resistant buffer material and has better performance.

*Low density and light weight: the density range is 0.5-0.8g/cm3, which is about 15% of aluminum when the density is the lowest compared with compact aluminum;

*Heat resistance: the temperature can reach 660 degrees Celsius, the melting point of the base aluminum;

*Rigidity: The bending specific stiffness can be better than that of steel. It is not malleable like dense metal. Under strong pressure, its porous structure will not reach the level of destruction and will not deform;

*Impact resistance: It is not directional like honeycomb, nor is it resilient like polymer materials. It is longer than absorbing impact energy;

*Permeability: open-cell aluminum foam pores are connected, three-dimensional opening, breathable and liquid-permeable;

*Sound absorption performance: When the sound wave frequency is between 125---2000HZ, the maximum sound absorption coefficient can reach 0.95, and the noise reduction coefficient exceeds 0.4.

*Thermal insulation performance: The thermal conductivity coefficient is about 1/400 of pure aluminum;

*Electromagnetic shielding performance: When the electromagnetic wave frequency is between 2.6-18GHZ, the electromagnetic shielding capacity of foamed aluminum can reach 60-90dB.

*Resistivity: 100 times that of pure aluminum;

*Corrosion resistance: good weather resistance, low moisture absorption, non-aging, non-toxic.

Spherical structure

The spherical bubble cabin, round-wall holes, and aluminum walls are relatively regular, so that the spherical hole type has superior energy absorption and impact resistance. Compared with the closed-cell type produced by gas foaming and slow-release foaming, it has stronger resistance to impact energy. Compared with other types of open-cell aluminum foam, the compressive (44Mpa) and bending (27Mpa) strength of the spherical open-cell type are also much higher.

At present, all open-cell aluminum foam materials in China are produced using industrial salt as raw materials, which is polluting. The produced materials are very corrosive due to the use of salt. They are not environmentally friendly products and cannot enter the national standard.

Standard size of Plate: 500mm * 500mm * 5-150mm

1000mm * 400mm * 5-150mm

Profiles: According to customer needs and customers to design and negotiate, the processing content includes cutting, bending, joining, compounding, etc.

Quality control standard table

|

Item |

Performance requirements |

|

|

National standard |

our standard |

|

|

Bulk density,g/cm3 |

0.2~0.8 |

|

|

Compressive strength σs ,Mpa |

2.40~20.0 |

44 |

|

Bending strength σbb,Mpa |

4.00~13.5 |

27 |

|

Noise reduction coefficient |

≥0.45 |

0.48 |